What is a Slitter Cutter Machine and How Does It Work?

The Slitter Cutter Machine plays a vital role in manufacturing. Industries rely on this equipment for precise cutting of materials. For instance, according to a 2022 report by MarketsandMarkets, the global slitting machine market is projected to reach $3.1 billion by 2026, driven by increased demand for packaged goods.

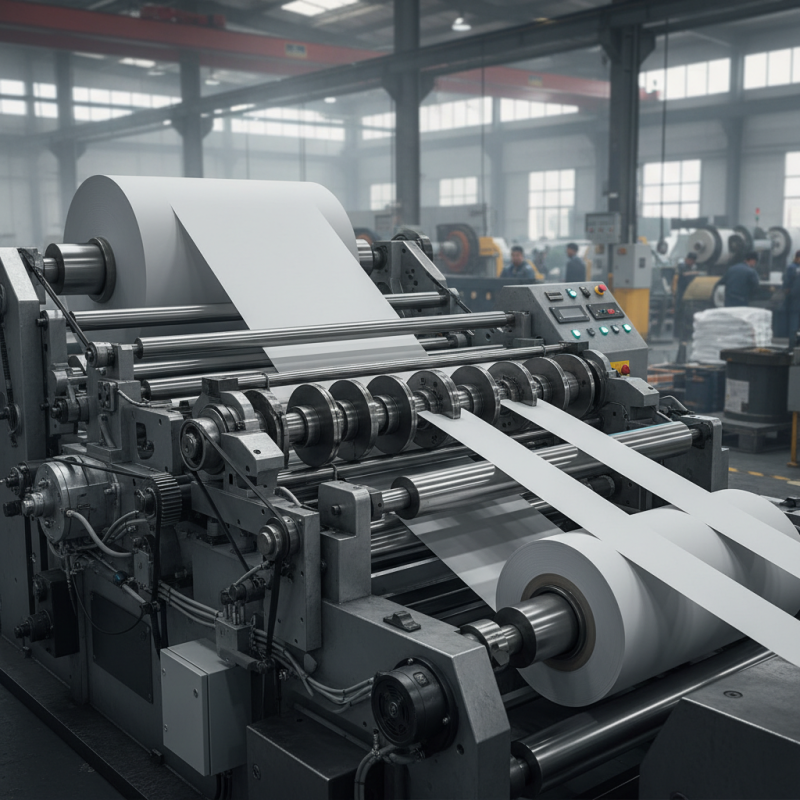

These machines efficiently slice large rolls of material into narrower strips. This process is essential in sectors like paper, film, and textiles. However, users often overlook the importance of machine maintenance. Failure to perform regular upkeep can lead to production delays and increased costs.

Moreover, not all Slitter Cutter Machines are created equal. Variants exist based on material types and thicknesses. It is crucial for businesses to choose the right machine, as improper selection may hinder efficiency. Understanding the operational mechanics of these machines is equally vital for maximizing their potential.

What is a Slitter Cutter Machine?

A slitter cutter machine is a specialized tool used in manufacturing to cut materials into narrower strips. Commonly used for paper, plastic, and textiles, these machines play a crucial role in ensuring materials meet specific widths and lengths for various applications. According to industry reports, the global slitter market is expected to grow by 5% annually, driven by increasing demand across multiple sectors.

The way a slitter cutter works is quite efficient. Material is fed into the machine, where it passes through a series of sharp blades. These blades can be adjusted to achieve different cut widths. Some models feature a rotary mechanism for continuous cutting, while others use flat blades for a more precise angle. Dust and waste can often accumulate, indicating the need for regular maintenance.

**Tips:** Always calibrate the machine to ensure precision. Regular blade changes can minimize errors and improve quality. If you notice excessive noise or vibration, it may indicate misalignment. Keeping the workspace clean can enhance operational efficiency and safety.

Key Components of a Slitter Cutter Machine

A slitter cutter machine is designed for precision cutting of materials into narrower strips. Understanding its key components is essential for its effective operation. The blade assembly is crucial. It holds the cutting blades, which can vary in size depending on the application. The adjustment mechanism allows for precise positioning of the blades, ensuring uniform cuts across the material.

Another important part is the feed mechanism. This controls how the material is fed into the machine. An improper feed can lead to uneven cuts or even damage the material. The tensioning unit keeps the material taut during the cutting process. This component is often overlooked, yet it can drastically affect the quality of the cuts.

**Tips:** Regular maintenance of the blades is vital. Dull blades can lead to poor quality cuts and wasted material. Additionally, always check the alignment before running a batch. A misaligned blade can ruin an entire roll, causing unnecessary waste. Keeping the machine clean also helps in maintaining its efficiency. Dust and debris can interfere with the cutting process and cause downtime.

How Slitter Cutter Machines Operate: A Step-by-Step Process

A slitter cutter machine is designed for cutting large rolls of material into narrower strips. Understanding how it operates can help businesses optimize their processes.

The machine uses sharp blades to slice through the material. Operators load the material onto the machine, ensuring it is aligned correctly. The material passes through the blades, which adjust for the desired width. After cutting, the strips are collected onto separate reels, ready for further use.

Tips: Always check the alignment before starting. Misalignment can cause uneven cuts. Regularly maintain the blades to ensure precise cutting. Dull blades can lead to waste and errors.

During operation, constant monitoring is essential. If the machine jams, it can halt production. Operators should be trained to handle these situations promptly. Improper handling could damage the machine or the material. Keep an eye on the tension of the material as well; overly tight material can cause problems.

In the end, attention to detail can make a significant difference. Adjusting settings based on the material type is crucial. Neglecting these factors can lead to unsatisfactory results.

Applications of Slitter Cutter Machines in Various Industries

Slitter cutter machines have diverse applications across various industries. In the packaging sector, these machines create precise cuts in flexible materials like plastic films and paper. With their high-speed operation, they improve productivity significantly. The accuracy of the cuts ensures that materials fit perfectly into packaging designs. This precision also minimizes waste, which is a crucial aspect in today’s eco-conscious market.

In the textile industry, slitter cutters play a key role in processing fabrics. They can cut rolls of material into narrower strips necessary for different clothing items. The speed of these machines helps meet large-volume demands. However, improper setup can lead to uneven cuts, requiring operators to double-check settings regularly. This aspect often challenges manufacturers, prompting them to rethink their workflow processes.

Moreover, the automotive industry uses slitter cutters for metal sheets. These machines help create shapes essential for car parts. Despite their efficiency, issues such as blade dullness can arise, impacting the final product quality. Continuous maintenance and inspection are vital to prevent these complications. This highlights the importance of balancing technology with skilled labor to achieve the best results.

Maintenance Tips for Optimal Performance of Slitter Cutter Machines

Regular maintenance is crucial for slitter cutter machines to ensure optimal performance. According to industry reports, nearly 30% of machine downtime is due to inadequate maintenance. This statistic highlights the need for a proactive approach. Operators should regularly check blades for wear and tear. Dull blades can cause poor cutting quality, leading to increased waste and lower efficiency.

Lubrication is another critical aspect. A well-lubricated machine reduces friction and prolongs equipment life. However, using the wrong lubricant can be detrimental. Inadequate lubrication may result in overheating or faster wear of machine parts. It's essential to follow the manufacturer's specifications for lubricants. Regularly scheduled inspections help in identifying potential issues early.

Additionally, keeping the machine clean is often overlooked. Dust and debris can accumulate, impacting performance. Cleaning should be part of the routine maintenance checklist. Neglect can lead to malfunctions or degraded product quality. Performance issues often stem from these small details. Engaging operators in simple maintenance tasks fosters a culture of care and awareness toward the machine's needs.

What is a Slitter Cutter Machine and How Does It Work? - Maintenance Tips for Optimal Performance of Slitter Cutter Machines

| Feature | Description | Importance |

|---|---|---|

| Blade Type | Rotary or flat blades used for cutting | Determines the quality of the cut |

| Feed Rate | Speed at which material is fed into the machine | Affects overall productivity |

| Material Thickness | Thickness of the material being cut | Influences cutting efficiency |

| Machine Alignment | Proper positioning of blades | Ensures accurate cuts without defects |

| Maintenance Schedule | Regular checks and servicing of the machine | Prolongs machine life and maintains performance |