Damper Actuator Tips for Optimal Performance and Maintenance?

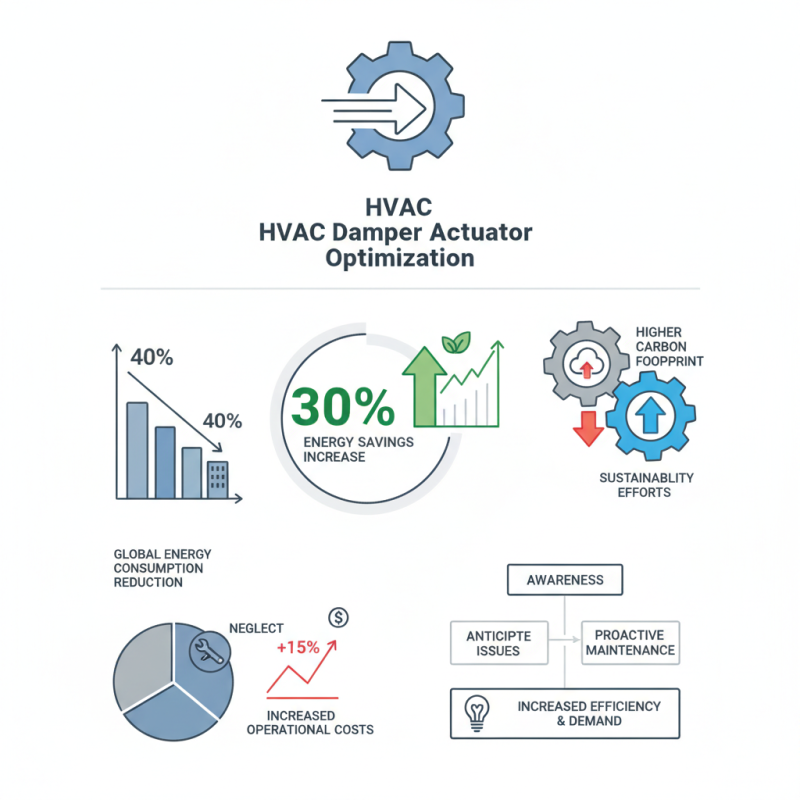

The performance of a Damper Actuator significantly impacts HVAC efficiency. According to industry reports, optimal operation can enhance energy savings by up to 30%. This is critical as buildings account for nearly 40% of global energy consumption. Regular maintenance of damper actuators is essential, yet often overlooked.

Many facilities neglect this task, leading to reduced performance and increased operational costs. Inefficient actuators cause airflow issues and temperature imbalances. Such problems can escalate maintenance costs significantly over time, sometimes by over 15%. Furthermore, outdated actuators can contribute to higher carbon footprints, challenging sustainability efforts.

Awareness of damper actuator functionality can guide better maintenance practices. Understanding its role helps in anticipating issues early. Implementing proactive measures is often harder than it seems, yet highly beneficial. As efficiency demands rise, attention to damper actuators must increase.

Overview of Damper Actuators and Their Functions

Damper actuators play a crucial role in HVAC systems. They control the flow of air in ducts. Efficient airflow is vital for maintaining temperature and indoor air quality. These devices modulate dampers, adjusting airflow as needed.

Understanding the function of damper actuators helps in their maintenance. Various types exist, each serving specific needs. Some are electric, while others are pneumatic. Regular checks on their responsiveness can prevent unwanted airflow issues. Ensuring correct alignment with dampers is necessary for optimal performance.

Neglecting routine inspections can lead to problems. Dust accumulation on actuators may hinder performance. It's important to be mindful of this aspect. Inspecting connections and power sources can reveal potential faults. Failing to address small issues might result in larger system failures. Taking the time to understand these devices enhances both efficiency and lifespan.

Key Factors Affecting Damper Actuator Performance

Damper actuators play a crucial role in HVAC systems. They control airflow, ensuring efficiency and comfort. Several factors influence their performance. Understanding these can help optimize operation.

Temperature is vital. Extreme heat or cold can affect actuator responsiveness. Regular checks are necessary. Humidity levels also impact performance. Moisture can lead to corrosion. Keeping dampers clean and dry is essential.

Maintenance tips include regular lubrication. It helps reduce wear and tear. Inspecting wiring connections can prevent unexpected outages. Sometimes, actuators may operate inefficiently due to misalignment or dirt accumulation. Addressing these issues promptly is crucial. Remember, even minor adjustments can significantly enhance operation.

Routine Maintenance Practices for Damper Actuators

Routine maintenance practices for damper actuators are crucial for their longevity and efficiency. Regular inspections should be a priority. Look for signs of wear or corrosion on the actuator housing. Lubricating moving parts helps reduce friction, ensuring smooth operation. A small amount of lubricant can go a long way.

Checking electrical connections is also essential. Loose wires can lead to erratic performance. It’s easy to overlook this, yet it’s a common issue. Cleaning the connections helps prevent malfunctions; a simple wipe can make a significant difference.

Operating conditions affect performance too. Dust and debris can accumulate, leading to mechanical failure. Make sure the environment remains clean. In cases of fluctuating temperatures, ensure the actuator functions within specified limits. Regular testing under various conditions can uncover hidden problems. This approach creates opportunities for improvement, enhancing overall performance.

Damper Actuator Tips for Optimal Performance and Maintenance

| Maintenance Task | Frequency | Description | Performance Indicator |

|---|---|---|---|

| Visual Inspection | Monthly | Check for any physical damage or wear on actuators. | No visible damage |

| Lubrication | Quarterly | Apply appropriate lubricant to moving parts to reduce friction. | Smooth operation |

| Electrical Check | Semi-Annual | Inspect connections and test for proper voltage and current. | Consistent voltage readings |

| Calibration | Annually | Ensure actuator responds accurately to control signals. | Accurate response time |

| Replacement of Components | As Needed | Replace worn-out or damaged parts based on inspection results. | Minimized downtime |

Common Issues and Troubleshooting for Damper Actuators

Damper actuators play a critical role in HVAC systems. However, they can face several common issues that impede performance. One frequent problem is the actuator’s inability to respond correctly to control signals. A study shows that approximately 30% of HVAC systems encounter issues related to actuator response. This often stems from improper calibration or mechanical binding.

Another issue is wear and tear on components due to prolonged use. Grease, dust, and debris can accumulate, causing the actuator to malfunction. Regular maintenance can help prevent this. According to industry reports, 20% of failures are attributed to inadequate maintenance routines.

Users should also consider the environment. High humidity can affect actuator performance. Monitor the conditions where actuators are installed. Neglecting environmental factors can lead to premature failures. Frequent inspections can identify these issues early, allowing for timely intervention. Often, troubleshooting involves checking power supply and connections first. A simple inspection might reveal loose wires or damaged connectors, solving the issue quickly. Awareness and proactive measures lead to better actuator lifespan and efficiency.

Best Practices for Maximizing Damper Actuator Efficiency

In the realm of damper actuators, maximizing efficiency is key. Studies show that proper maintenance can enhance performance by up to 25%. Regular inspection is crucial. A slight misalignment can lead to inefficiencies and increased wear. Schedule checks every six months.

One common oversight is neglecting lubrication. Lubricating the actuator mechanism reduces friction. This simple step prolongs its lifespan. Reports reveal that well-lubricated actuators operate 30% more efficiently than dry ones. Still, over-lubrication can attract dust and debris. Strike a balance to avoid future issues.

Temperature control is often overlooked. Extreme temperatures can affect actuator performance. Data indicate that operating outside recommended conditions can decrease efficiency by 20%. Regular assessment of the operating environment helps prevent these performance dips. Evaluating these aspects is essential for effective damper actuator management.

Damper Actuator Efficiency Metrics

This chart illustrates the performance metrics of damper actuators, highlighting critical factors such as response time, power consumption, temperature range, maintenance frequency, and overall efficiency. Proper attention to these metrics can significantly enhance damper actuator performance and reliability.